The restoration of classic cars is a meticulous process that requires attention to detail and authenticity. Traditional restoration methods can be time-consuming and expensive, especially when sourcing rare or obsolete parts.

3D printing has emerged as a game-changing technology in the restoration of classic cars, offering numerous advantages in terms of precision, cost, and efficiency. Here’s how 3D printing is revolutionizing classic car restoration:

1. Reproducing Obsolete Parts

Digitizing Original Components

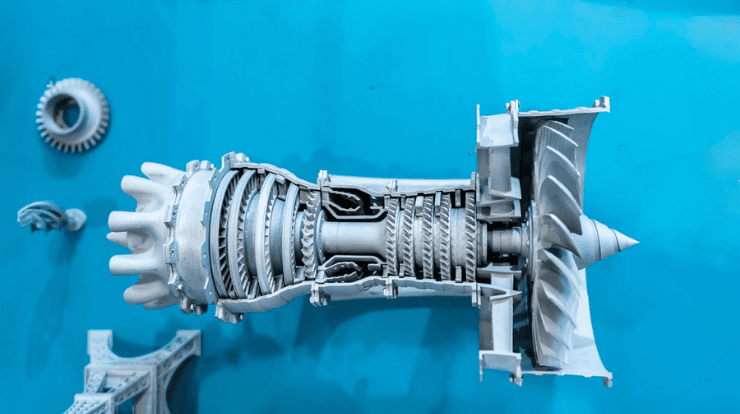

One of the significant challenges in classic car restoration is finding replacement parts that are no longer in production. 3D printing addresses this issue by allowing restorers to reproduce obsolete parts accurately. The process begins by digitizing the original component using 3D scanning technology. This creates a precise digital model that can be used to produce an exact replica of the part.

Custom Fabrication

Even when original parts are unavailable, 3D printing enables the custom fabrication of components based on specifications or original designs. Restorers can create parts that perfectly match the original in terms of dimensions, material properties, and functionality.

This capability is particularly valuable for rare and unique vehicles where replacement parts are almost impossible to find.

2. Enhancing Accuracy and Detail

Precision Engineering

3D printing allows for precision engineering of components, ensuring that every detail is captured and replicated accurately. This level of precision is crucial for maintaining the authenticity of classic cars. Whether it’s an intricate grille, a detailed emblem, or a complex engine component, 3D printing ensures that every part is an exact match to the original.

Material Matching

Advancements in 3D printing materials mean that restorers can select materials that closely match the original components in terms of strength, weight, and finish. From metals like aluminum and titanium to high-strength plastics, the variety of available materials ensures that the restored parts meet or exceed the quality of the originals.

3. Cost and Time Efficiency

Reducing Lead Times

Traditional manufacturing processes for replacement parts can involve long lead times, especially when custom tooling or molds are required. 3D printing significantly reduces these lead times by enabling on-demand production. Parts can be printed as soon as the digital model is ready, allowing restorers to move forward with their projects more quickly.

Lowering Costs

The cost of producing replacement parts using traditional methods can be prohibitive, particularly for low-volume or one-off components. 3D printing eliminates the need for expensive tooling and molds, reducing overall production costs. This cost efficiency makes it feasible to restore classic cars that might otherwise be too expensive to repair.

4. Customization and Adaptation

Tailoring Parts to Specific Needs

In some cases, restorers may need to adapt parts to fit modified or upgraded components. 3D printing allows for easy customization of parts to accommodate these changes. Whether it’s adjusting the dimensions of a bracket to fit a modern engine or creating a bespoke mount for a new suspension system, 3D printing provides the flexibility needed to tailor parts to specific needs.

Creating Unique Features

For classic car enthusiasts looking to add unique features to their vehicles, 3D printing offers endless possibilities. Custom badges, personalized interior elements, and bespoke exterior trims can all be created with 3D printing. This customization enhances the individuality of classic cars while maintaining their historical integrity.

5. Prototyping and Testing

Rapid Prototyping

Before committing to the final production of a replacement part, restorers can use 3D printing for rapid prototyping. This allows them to test the fit and function of the part in the vehicle, ensuring that it meets all requirements. Rapid prototyping helps identify any potential issues early in the process, reducing the risk of costly errors.

Iterative Development

3D printing supports an iterative development process, where multiple versions of a part can be produced and tested until the optimal design is achieved. This iterative approach is particularly useful for complex components that require fine-tuning to achieve the perfect fit and performance.

6. Preserving Historical Accuracy

Maintaining Authenticity

One of the primary goals of classic car restoration is to maintain historical accuracy. 3D printing allows restorers to create parts that are faithful reproductions of the originals, preserving the vehicle’s authenticity. This attention to detail ensures that restored classic cars remain true to their heritage.

Documenting and Archiving Designs

The digital models created for 3D printing can be archived for future use, creating a valuable repository of designs. This documentation ensures that even if a part is needed years down the line, the design can be easily accessed and reproduced. This archival capability is crucial for preserving the legacy of classic cars.

Conclusion

In conclusion, 3D printing is transforming the restoration of classic cars by providing accurate, cost-effective, and efficient solutions for reproducing obsolete parts, enhancing detail and precision, and offering customization options.

This technology not only preserves the authenticity and historical value of classic vehicles but also makes the restoration process more accessible and feasible. As 3D printing continues to evolve, its impact on classic car restoration will only grow, opening up new possibilities for preserving automotive heritage.